APLIKACE

WST

Water Scan Toolbox

Aplikace Water Scan Toolbox (WST) představuje soft senzor umožňující predikci kvality nátoku odpadních vod do čistírny odpadních vod.

•Aplikace poskytuje informace o složení odpadní vody bez potřeby investice do nákladné S:CAN sondy, čímž přispívá k úsporám na provozních nákladech.•Predikce množství a kvality přitékající odpadní vody pomáhá předcházet provozním komplikacím.•Intuitivní systém zároveň upozorňuje na plánované i neplánované události, což zajišťuje efektivní provoz.

Aplikace

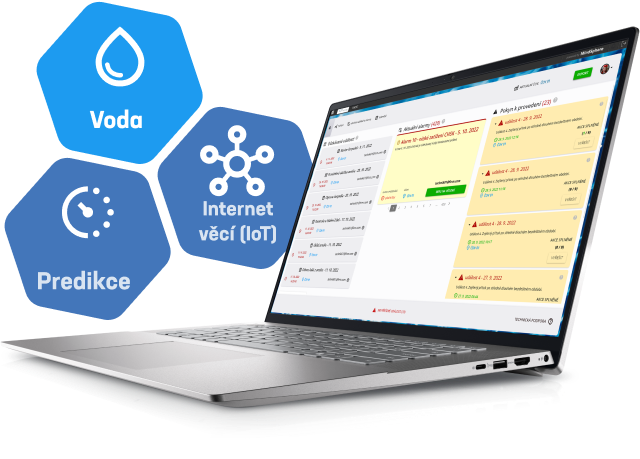

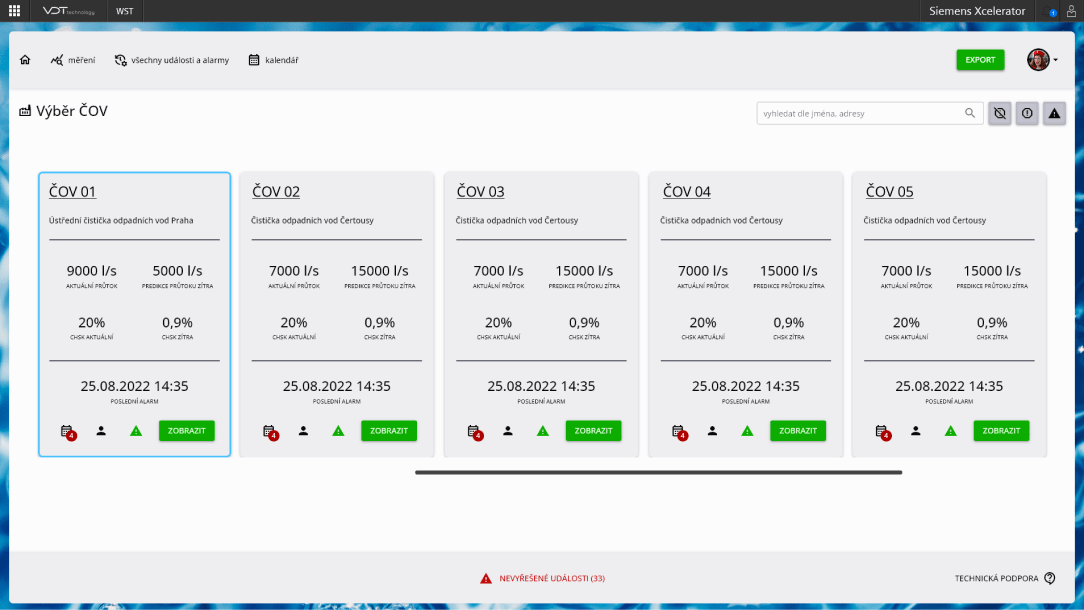

Vzhled

APLIKACE WST

O aplikaci

Predikce a plánování

WST využívá prediktivní modelování na bázi samoučících se algoritmů k předpovědi množství a kvality přitékající odpadní vody do provozu. Tato technologie umožňuje provozovatelům čistíren odpadních vod lépe se připravit na různé provozní stavy, zejména během přívalových dešťů.Klíčové vlastnosti:- •Prediktivní modely založené na matematických modelech a neuronových sítích.

- •Databáze scénářů pro různé provozní stavy.

- •Rozhodovací matice pro optimální reakci na předpovězené události.

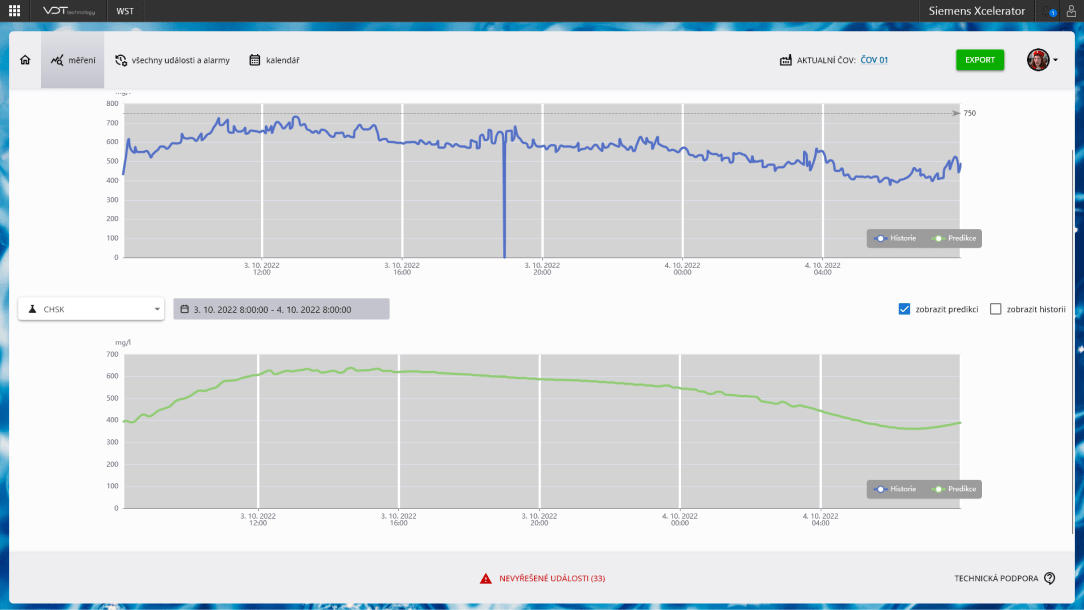

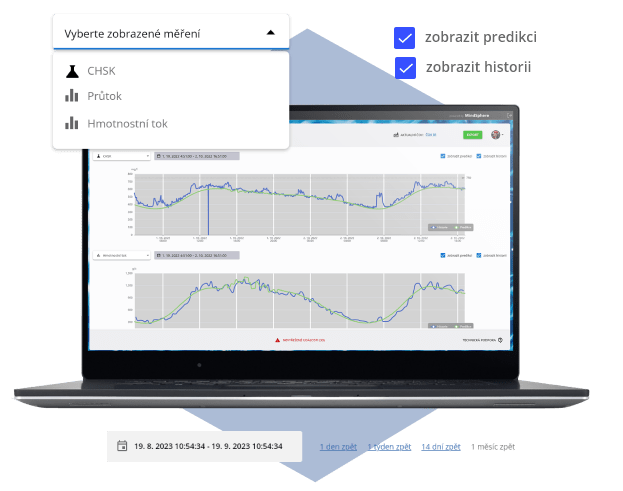

Vizualizace a Analýza Dat

Jedním z klíčových prvků aplikace WST je schopnost vizualizovat jak predikované, tak naměřené hodnoty, což uživatelům poskytuje cenný přehled o provozu a usnadňuje analýzu dat. Tento nástroj umožňuje lépe pochopit chování procesů v čistírnách odpadních vod a podporuje efektivnější rozhodování.- •Přehledné grafy: Data jsou prezentována ve formě intuitivních grafů, které umožňují snadné porovnání měřených a predikovaných hodnot. Uživatelé tak mohou rychle identifikovat odchylky nebo trendy.

- •Historická analýza: Možnost přístupu k datům až jeden rok zpětně napomáhá lepšímu pochopení dlouhodobých procesů a výkonnosti zařízení.

- •Export dat: Uživatelé mohou jednoduše exportovat vizualizovaná data do formátů vhodných pro další zpracování, například v analytických nástrojích.

Tato sekce podporuje efektivní řízení a optimalizaci provozu díky lepší informovanosti.

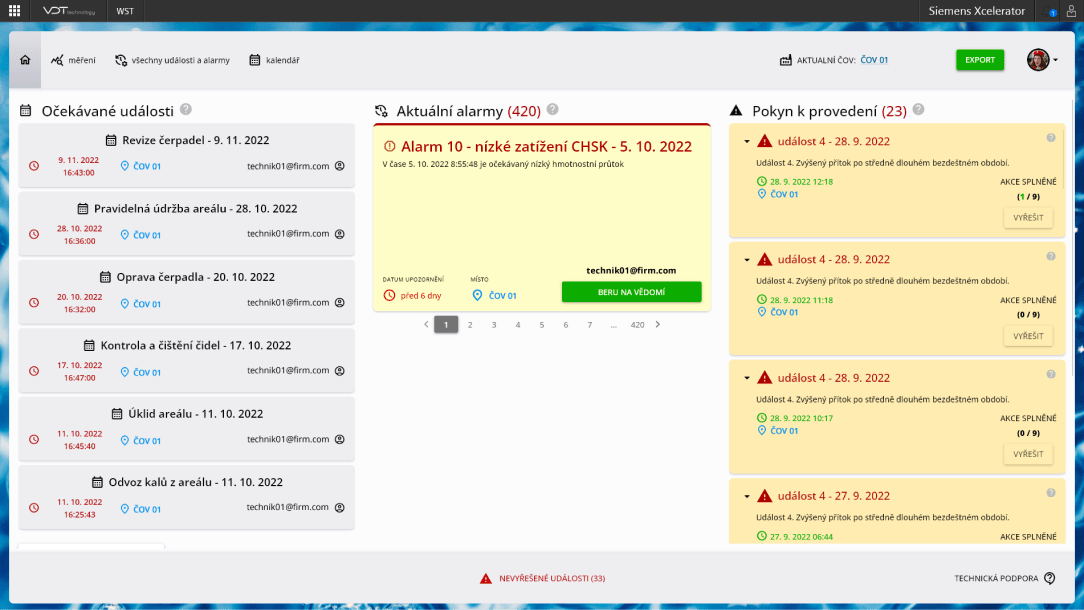

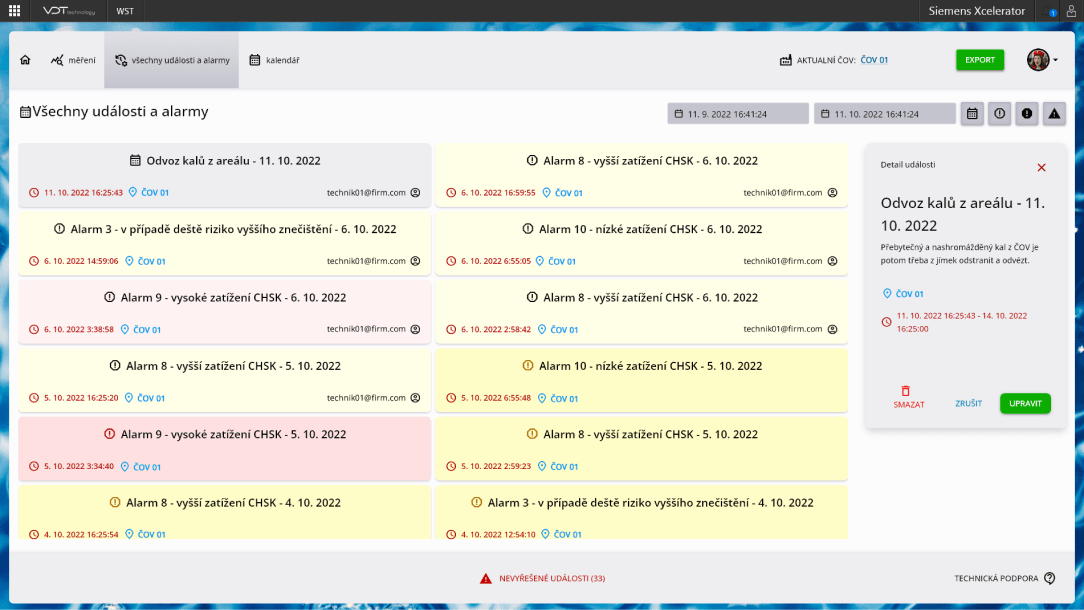

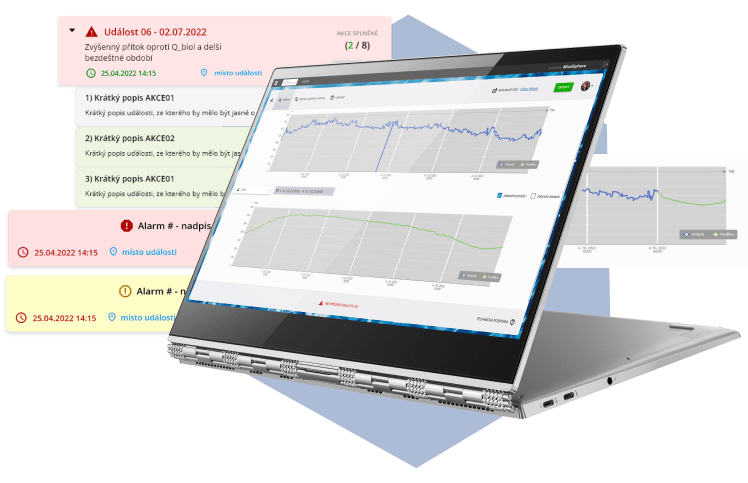

Systém událostí

WST obsahuje integrovaný systém upozornění, který na základě definovaných alarmů informuje o rizikových situacích, například o vysokém látkovém zatížení po bezdeštném období. Tato funkcionalita umožňuje rychlou reakci na potenciální rizika a zajišťuje, že provoz je připraven na různé situace.- •Přehled plánovaných i neplánovaných událostí.

- •Automatické generování upozornění na základě predikovaných dat.

- •Kategorizace upozornění podle závažnosti a potřebných akcí.

- •Generování událostí s podřízenými úkony vyžadující fyzické splnění přímo v provozu.

- •Schvalování a příjímání existujících událostí.

- •Historie událostí a alarmů pro sledování a analýzy trendů.

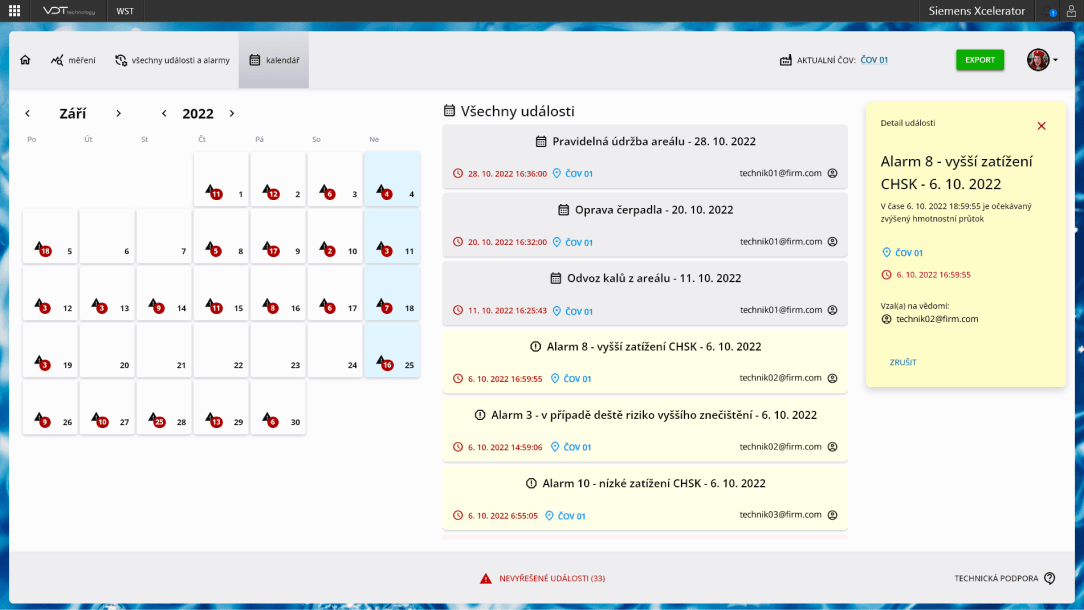

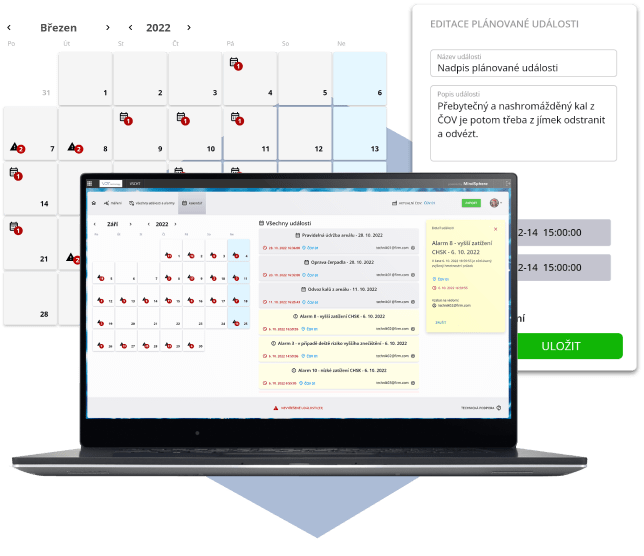

Kalendář událostí

Integrovaný kalendář v aplikaci nabízí uživatelům nástroj pro správu všech provozních aktivit, ať už plánovaných nebo neplánovaných. Tato funkce zlepšuje organizaci práce a umožňuje efektivnější řízení provozu.- •Rychlý přehled o událostech: Uživatelé mohou snadno sledovat plánované úkoly, údržbu, i nečekané události a alarmy, což přispívá k přehlednosti a organizovanosti.

- •Koordinace činností: Kalendář usnadňuje plánování a řízení provozních aktivit, čímž podporuje efektivní spolupráci mezi jednotlivými týmy nebo pracovníky.

- •Včasná reakce: Díky zobrazení kritických událostí uživatelé mohou reagovat rychle a adekvátně, což minimalizuje riziko provozních výpadků nebo problémů.

Tato sekce je praktickým nástrojem pro každodenní operativu, který zajišťuje hladký chod a optimalizaci procesů.

JAK NÁS KONTAKTOVAT

Zaujal Vás náš produkt

OBLAST DOTAZUObchod a realizace

T+420 277 004 040